Introduction

Scandium and steel are two materials that play pivotal roles in modern technology and industry. While scandium is a rare earth metal known for its unique properties and high value in specialized applications, steel is an alloy that has been fundamental to construction and manufacturing for centuries. This article explores the similarities and differences between scandium and steel, examining their properties, applications, and significance.

Basic Properties

Scandium

- Symbol: Sc

- Atomic Number: 21

- Density: 2.985 g/cm³

- Melting Point: 1541°C

- Appearance: Silvery-white metal

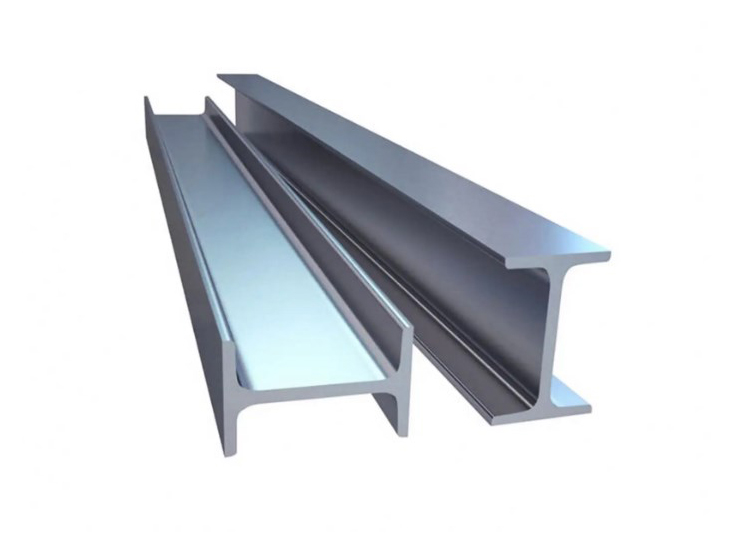

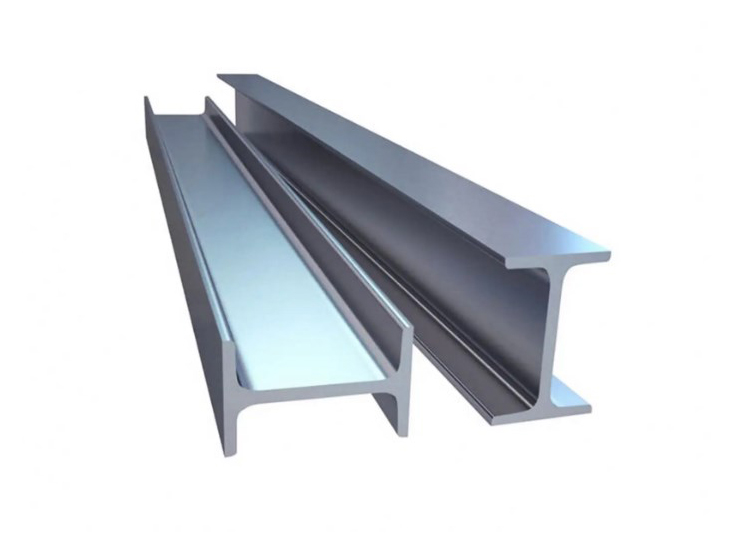

Steel

- Composition: Primarily iron (Fe) with carbon (C) and other alloying elements

- Density: Typically around 7.85 g/cm³ (varies with alloy composition)

- Melting Point: Varies (typically around 1370°C to 1510°C depending on the alloy)

- Appearance: Gray or bluish-gray, metallic luster

Scandium is a pure element with a consistent set of properties, whereas steel is an alloy whose properties can vary widely depending on the specific composition of iron, carbon, and other elements.

Chemical Behavior

Similarities

- Alloying Capabilities: Both scandium and steel can be alloyed with other elements to enhance their properties. Scandium is often added to aluminum, while steel can be alloyed with elements like chromium, nickel, and manganese to create various types of steel with different properties.

- Corrosion Resistance: Both materials can be treated or alloyed to improve corrosion resistance. Scandium alloys with aluminum to enhance corrosion resistance, while stainless steel, which contains chromium, is highly resistant to corrosion.

Differences

- Reactivity: Scandium is a rare earth metal and reacts with oxygen to form scandium oxide (Sc₂O₃), providing a protective coating. Steel, being primarily iron, can rust (iron oxide) when exposed to moisture and oxygen unless it is alloyed with other elements like chromium to form stainless steel.

- Oxidation States: Scandium typically exhibits a +3 oxidation state, while steel, depending on its composition, can exhibit various oxidation states influenced by its iron content.

Applications

Scandium

- Aerospace: Scandium is used in aluminum-scandium alloys to produce lightweight, strong components for aerospace applications. Read more: Aluminum-Scandium Alloys: A Future Bright with Lightweight Solutions

- Sports Equipment: High-performance sports equipment, such as bicycle frames and baseball bats, often incorporates scandium for enhanced strength and durability.

- Lighting: Scandium is used in metal halide lamps, providing high-intensity light with excellent color rendering properties.

- Solid Oxide Fuel Cells (SOFCs): Scandium is used to improve the conductivity and performance of electrolyte materials in SOFCs.

Steel

- Construction: Steel is a fundamental material in construction, used in buildings, bridges, and infrastructure due to its strength and durability.

- Automotive Industry: Steel is extensively used in the manufacture of cars and trucks, providing structural integrity and safety.

- Manufacturing: Steel is used in the production of machinery, tools, and appliances due to its versatility and strength.

- Shipbuilding: Steel’s strength and resistance to corrosion (when alloyed) make it ideal for shipbuilding.

While scandium is used in specialized, high-performance applications, steel is ubiquitous in a wide range of industries due to its versatility and cost-effectiveness.

Economic and Industrial Relevance

Scandium

Scandium is a rare element with limited primary production sources, often obtained as a by-product of other mining operations. Its high cost and limited availability restrict its use to niche applications where its unique properties provide significant advantages.

Steel

Steel is one of the most widely used materials in the world, with a well-established and extensive supply chain. It is produced in massive quantities and is relatively inexpensive, making it a cornerstone of industrial and economic development.

Environmental and Biological Aspects

Environmental Impact

Both scandium and steel have environmental impacts associated with their extraction and processing. Steel production, in particular, is energy-intensive and can contribute to greenhouse gas emissions. However, steel is highly recyclable, which helps mitigate some of its environmental impact. Scandium’s environmental footprint is smaller due to its limited production volume, but sustainable practices are necessary to manage its extraction.

Biological Roles

Neither scandium nor steel play significant biological roles in the human body. Steel, being an alloy, does not have biological significance, though iron, its primary component, is essential for human health. Scandium, while generally considered non-toxic, does not have a known biological function and should be handled with care to avoid potential health risks from prolonged exposure.

Conclusion

Scandium and steel, while both crucial in their respective domains, exhibit distinct properties and applications. Scandium’s role in enhancing aluminum alloys and its use in high-performance lighting and fuel cells highlight its specialized contributions to modern technology. In contrast, steel’s versatility, strength, and widespread use underscore its foundational importance in construction, manufacturing, and numerous other industries.

Understanding the similarities and differences between these materials allows for their optimal application in various fields, driving innovation and improving material performance. For more information on scandium and its applications, explore our comprehensive resources and product offerings on our website. Discover how scandium can elevate your projects and meet your specific needs in the ever-evolving world of materials science.