Scandium, a rare and remarkable element, sits discreetly in the periodic table, often overlooked but possessing unique properties that make it invaluable in various industrial applications. This article delves into the occurrence of scandium in nature, explores the methods employed for its extraction, and investigates the technological advancements that have shaped the extraction processes over time.

Occurrence of Scandium: A Scarcity in Earth’s Crust

Scandium, with the atomic number 21, is not abundant in the Earth’s crust. Its scarcity presents a challenge for industries seeking to harness its exceptional properties. The primary natural sources of scandium include certain minerals and ores, with scandium often found as a trace element rather than in concentrated deposits.

Related Article: A Historical Journey into the Discovery of Scandium

One notable source is thortveitite, a rare scandium-rich silicate mineral. Other minerals like euxenite and gadolinite may also contain traces of scandium. However, the concentration of scandium in these minerals is typically low, requiring advanced extraction methods to obtain usable quantities.

Extraction Techniques: Navigating the Complexities

Extracting scandium from its natural sources is a complex process due to its low abundance and the need for precision in separating it from other elements. Over the years, various extraction techniques have been developed, each with its advantages and challenges.

1. Hydrometallurgical Processes:

One common method involves hydrometallurgical processes, where ores containing scandium are dissolved in acids, and selective precipitation or solvent extraction is employed to separate scandium from other elements. This method is effective but often requires careful control of conditions to achieve the desired purity.

2. Ion Exchange Chromatography:

Ion exchange chromatography is another technique used in scandium extraction. This method relies on the differential adsorption of ions onto a resin, allowing for the selective separation of scandium. While effective, this process is resource-intensive and may not be economically viable for large-scale production.

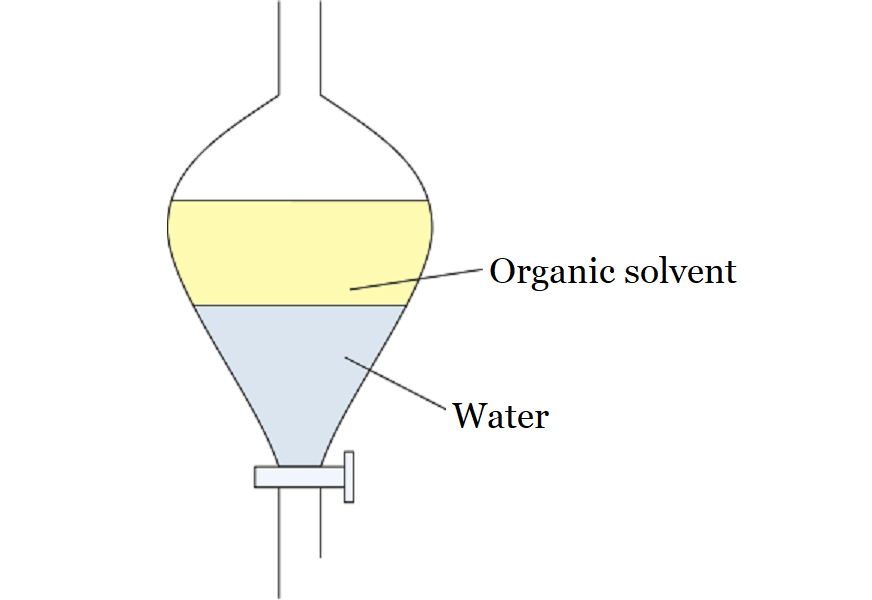

3. Solvent Extraction:

Solvent extraction is a widely used method for separating scandium from other elements. Organic solvents are employed to selectively extract scandium from the acidic solution, and subsequent purification steps yield a high-purity scandium product. This method is scalable and has been employed in industrial settings.

Technological Advancements: Paving the Way for Efficiency

The quest for efficient and sustainable scandium extraction has driven technological innovations, revolutionizing the way we obtain this rare element. Recent advancements focus on improving extraction efficiency, reducing environmental impact, and expanding the sources of scandium.

1. Reducing Environmental Impact:

Traditional extraction methods often involve the use of strong acids, raising environmental concerns. Recent innovations explore greener alternatives, such as the utilization of bioleaching processes where microorganisms assist in breaking down ores, reducing the need for harsh chemicals.

2. Recycling and Urban Mining:

As the demand for scandium grows, efforts are underway to explore recycling methods. Urban mining, or the recovery of valuable materials from electronic waste, presents an opportunity to extract scandium from discarded devices, contributing to both resource sustainability and waste reduction.

3. Exploration of New Deposits:

Advancements in geological survey techniques and exploration technologies have facilitated the discovery of new scandium deposits. Remote sensing and geochemical analyses aid in identifying areas with elevated scandium concentrations, potentially expanding the sources available for extraction.

Applications Driving Demand:

The unique properties of scandium, including its lightweight nature, high melting point, and corrosion resistance, make it a sought-after element in various industries.

The aerospace sector utilizes scandium alloys to create lightweight yet robust components, contributing to fuel efficiency and enhanced performance in aircraft.

In sports and recreation, scandium-aluminum alloys are employed in the production of high-performance equipment such as baseball bats and bicycle frames.

The defense and military sector leverages scandium materials for their strength and durability in applications ranging from aircraft construction to armor materials.

Conclusion: Navigating the Scandium Landscape

In conclusion, scandium, though scarce, holds immense potential in shaping the future of various industries. The exploration of new extraction methods, coupled with technological advancements, is unlocking opportunities to meet the growing demand for this rare element. As industries continue to innovate and leverage scandium’s unique properties, the journey of extracting this elusive element becomes not just a technological feat but a key driver in the evolution of materials science and industry.

Discover additional insights into scandium by visiting www.scandium.org.

Explore a wealth of information on other rare earth materials at www.stanfordmaterials.com.