Introduction

Scandium and vanadium are two transition metals that, despite being from different groups on the periodic table, share certain similarities and possess unique properties that make them valuable in various high-tech and industrial applications. This article explores the similarities and differences between scandium and vanadium, examining their properties, applications, and significance.

Basic Properties

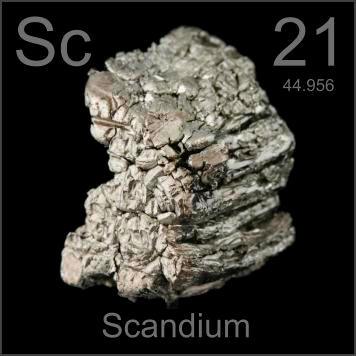

Scandium

- Symbol: Sc

- Atomic Number: 21

- Density: 2.985 g/cm³

- Melting Point: 1541°C

- Appearance: Silvery-white metal

Vanadium

- Symbol: V

- Atomic Number: 23

- Density: 6.11 g/cm³

- Melting Point: 1910°C

- Appearance: Silvery-gray metal

Both scandium and vanadium are transition metals with high melting points and metallic lusters. However, vanadium is denser and has a higher melting point than scandium, influencing their respective applications in industries that require materials to withstand high temperatures and stresses.

Chemical Behavior

Similarities

- Oxidation States: Both scandium and vanadium can exhibit multiple oxidation states. Scandium typically shows a +3 oxidation state, while vanadium can exhibit +2, +3, +4, and +5 states.

- Reactivity: Both metals form stable oxides (Sc₂O₃ for scandium and V₂O₅ for vanadium) and can be alloyed with other metals to enhance their properties.

Differences

- Chemical Versatility: Vanadium’s ability to exhibit multiple oxidation states makes it more chemically versatile compared to scandium, which primarily remains in the +3 state.

- Reactivity: Vanadium reacts with nonmetals such as nitrogen, forming nitrides like VN, which are hard and wear-resistant. Scandium’s reactions are less diverse compared to vanadium.

Applications

Scandium

- Aerospace: Scandium is used in aluminum-scandium alloys to produce lightweight, strong components for aerospace applications.

- Sports Equipment: High-performance sports equipment, such as bicycle frames and baseball bats, often incorporates scandium for enhanced strength and durability.

- Lighting: Scandium is used in metal halide lamps, providing high-intensity light with excellent color rendering properties.

- Solid Oxide Fuel Cells (SOFCs): Scandium is used to improve the conductivity and performance of electrolyte materials in SOFCs.

Vanadium

- Steel Production: Vanadium is primarily used to produce high-strength, low-alloy (HSLA) steel, enhancing its strength, toughness, and wear resistance.

- Aerospace: Vanadium alloys, such as titanium-vanadium, are used in aerospace applications for their high strength-to-weight ratio and ability to withstand high temperatures.

- Batteries: Vanadium is used in vanadium redox flow batteries, which are promising for large-scale energy storage due to their long cycle life and scalability.

- Chemical Catalysts: Vanadium pentoxide (V₂O₅) is used as a catalyst in sulfuric acid and other industrial processes.

While both metals are used in high-performance applications, scandium’s applications are more niche and specialized, whereas vanadium’s versatility allows it to be used in a broader range of industries.

Alloying

Scandium Alloys

Scandium’s primary application is in enhancing aluminum alloys, creating materials with superior strength, weldability, and corrosion resistance. These alloys are particularly valuable in the aerospace and sports equipment industries, where weight reduction and durability are crucial.

Vanadium Alloys

Vanadium is a critical alloying element in steel production, where even small amounts significantly improve the strength, toughness, and wear resistance of the steel. Vanadium alloys are essential in aerospace and automotive industries, providing materials that can withstand high temperatures and mechanical stress.

Economic and Industrial Relevance

Scandium

Scandium is a rare element with limited primary production sources, often obtained as a by-product of other mining operations. Its high cost limits its widespread use, but its ability to significantly enhance aluminum alloys creates a niche market with strong demand in aerospace and high-performance applications.

Vanadium

Vanadium is more abundant and has a well-established supply chain. It is extracted primarily from vanadium-bearing magnetite and other minerals. Vanadium’s broad range of applications, particularly in steel production and energy storage, makes it a critical material with significant economic importance.

Environmental and Biological Aspects

Environmental Impact

Both scandium and vanadium have relatively low environmental impacts when used properly. However, their extraction and processing can pose environmental challenges, requiring careful management to minimize adverse effects. Recycling and sustainable mining practices are essential to mitigate their environmental footprint.

Biological Roles

Neither scandium nor vanadium play significant biological roles in the human body. Scandium is generally considered non-toxic, while vanadium, although essential in trace amounts for some organisms, can be toxic in higher concentrations and should be handled with care to avoid potential health risks.

Conclusion

Scandium and vanadium, while sharing certain similarities as transition metals, exhibit distinct properties and applications that make them valuable in different ways. Scandium’s role in enhancing aluminum alloys and its use in high-performance lighting and fuel cells highlight its specialized contributions to modern technology. In contrast, vanadium’s versatility in steel production, aerospace, energy storage, and catalysis underscores its broader industrial significance.

Understanding the similarities and differences between these two metals allows for better utilization in specialized applications, driving innovation and enhancing material performance. For more information on scandium and its applications, explore our comprehensive resources and product offerings on our website. Discover how scandium can elevate your projects and meet your specific needs in the ever-evolving world of materials science.